inVia Picker robot

Nimble, adaptable, tireless team players

inVia Picker robots are small, safe, and easy-to-operate.

They fit right into your warehouse and your team,

and they operate autonomously – and tirelessly – to fulfill orders with precision.

______________

5x productivity boost with Goods-to-Person automation

Our robots work with machine precision and never get distracted, so you’ll see your error rates go down and accuracy rates go up. Plus, with our Robotics-as-a-Service (RaaS) model you don’t pay for robots. You only pay for the services they provide.

ADAPTABILITY

Ready for your warehouse – keep your existing infrastructure

inVia Picker robots are compact and durable, allowing them to adapt to your existing flooring and racking.

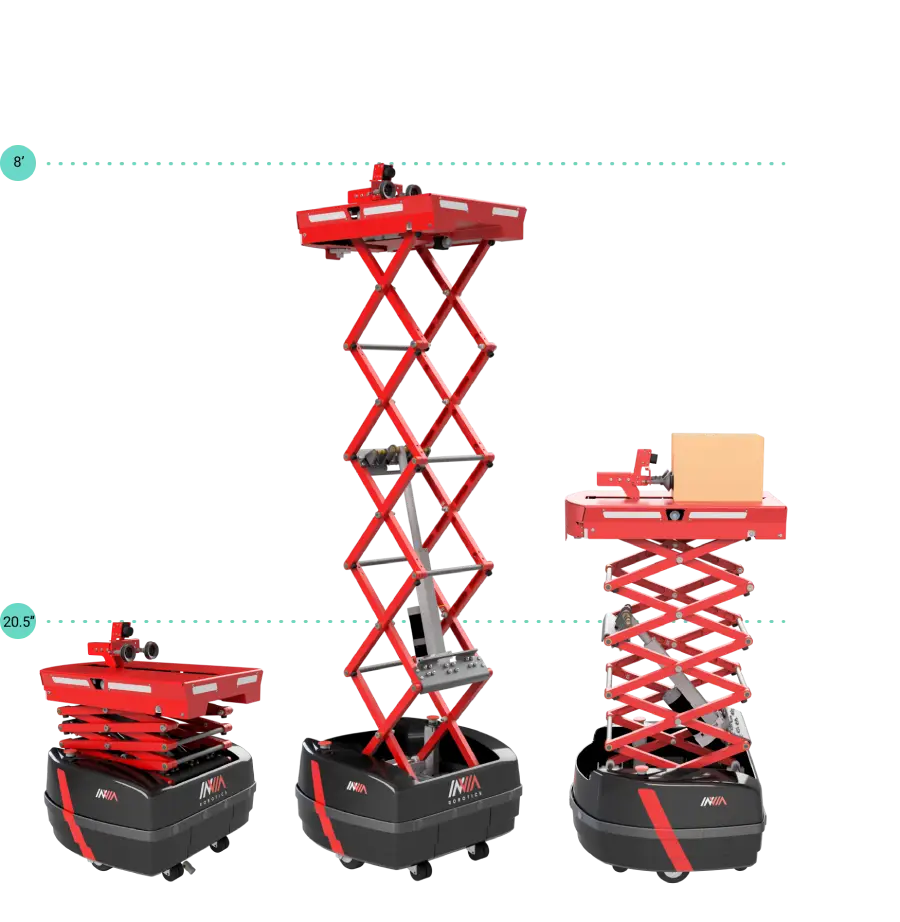

Our Autonomous Mobile Robots (AMR) use an extendable lift to reach upper shelves. Our patented solution uses industrial suction cups that seal a secure grip on your totes as they move through the warehouse.

AUTONOMY

No more walking the aisles

for miles!

inVia Picker robots work completely autonomously to automate all order fulfillment tasks. They retrieve and move goods, so your people are no longer spending their time walking through warehouse aisles. They’re spending their time getting orders out the door.

EFFICIENCY

Work independently, nonstop

Unlike other AMRs, our robots can get their work done without having to wait around for people to do theirs. Utilizing machine vision with “fiducial” stickers, our robots can detect the location of inventory with ultra-precision.

Hot-swappable batteries, a self-charging feature, and built-in lighting allows robots to see in the dark. That means you can run your operations nonstop, never wasting a second of valuable fulfillment time.

Make 1000 UPH pick rate your fulfillment reality

inVia PickerWall is a dynamic pick/put wall our robots build with each day’s orders. The robots work in rote fashion on one side of the wall, while people work in bursts on the other side, pulling products and sorting them into order bins. Costly warehouse walking is eliminated and workers can rotate freely across other warehouse tasks.

SPECIFICATIONS

inVia Picker: Small & Mighty Autonomous Mobile Robots

Dimensions

25.5”H x 26.1”W

Weight

136 lbs.

Payload Weight

Up to 40 lbs.

Payload Size

14”H x 15”W x 24”L

Reach

Up to 8 ft.

Max Speed

5 mph

Power

Hot-swappable 10-hr. battery;

Self-charging feature available

* Exact payload and reach calculated and approved in detailed system specifications by Sales Engineer

Dimensions

25.5”H x 26.1”W

Weight

136 lbs.

Payload Weight

Up to 40 lbs.

Reach

Up to 8 ft.

Max Speed

5 mph

Power

Hot-swappable 10-hr. battery;

Self-charging feature available

Go at your own pace

With a phased approach to warehouse technology adoption, inVia automation solutions meet the expectations of today and adapt to tomorrow's demand.

Option 1

Software Only

Option 2

Automated Labor

Option 3

Automated Warehouse

______________

What it does for you

Deliver goods-to-person efficiency at a fraction of the cost.

While many AMRs require people to walk with the robots through the warehouse, inVia Pickers do the traveling and bring goods to stationary pickers, eliminating costly walking.

Increase your speed.

With the ability to autonomously retrieve goods and work nonstop, inVia Pickers can decrease your cycle times and increase your productivity 5x.

Increase your accuracy.

Because robots work with machine precision and never get distracted, you’ll see your error rates go down and your accuracy rates go up.

Scale at will.

Because our robots are adaptable, your system can easily – and quickly – adjust to accommodate order volume growth. You can expand system capacity, or move the whole system to a bigger warehouse.

Request a Demo

Did you know that you can boost your productivity 2-3x with inVia Logic's AI automation solution and 5x when you add inVia Picker autonomous mobile robots?

Complete the form and a member of our team will contact you to conduct a demo that explains how you can increase your productivity with the inVia system.