Consumer expectations are often a product of our fast-paced surroundings. Thanks to automated callbacks in customer service, we avoid waiting on hold. Coffee can be ordered via an app to skip the line. With the onset of the on-demand economy, we opt for delivery instead of physically going to stores or restaurants. Ultimately, we crave convenience, speed, and ease.

Given these factors, it’s no surprise that global retail e-commerce sales are expected to exceed $4.5 trillion by 2021. However, the market growth doesn’t come without challenges for retailers and fulfillment centers. Namely, the demand for next-day (or same-day) delivery. In order to keep up with this pace set by industry behemoths like Amazon, e-commerce companies are seeking nimble, strategic and intuitive tools to stay competitive—namely, warehouse automation systems.

How is your team preparing to meet the increasingly difficult demands of the evolving e-commerce marketplace? Is your team ready for warehouse robotics? Here are a few factors to consider as you dive into the space.

Weigh the costs

Integrating a traditional, full-service automation system into your warehouse can be extremely costly. While this may be feasible for the Amazons, Targets and Walmarts of the world, it isn’t for most e-commerce companies, especially when considering implementation across several warehouse locations.

Alternatively, innovators in the autonomous mobile robot (AMR) space are offering new business models for supply chain automation that offer similar returns with significantly lower CapEx. inVia’s RaaS (Robotics-as-a-Service) platform does this using an affordable, scalable and subscription-based model. Customers are provided a service level agreement based on their specific throughput requirements. Upfront costs are minimal as all hardware is owned and managed by inVia, making RaaS viable in applications where robotic automation was previously prohibitively expensive. The subscription-based pricing is predictable and scalable according to the individualized needs of a customer’s operations. Robots, deployment and ongoing operating costs are included and companies simply pay a monthly subscription for the complete solution.

Consider the ROI and flexibility

E-commerce retailers experience major ebbs and flows in consumer demand based on peak shopping seasons, holiday deals and other varying factors. This likely means you’ll need more robots during back-to-school or holiday-driven shopping peaks, requiring a solution that’s highly adaptive and flexible.

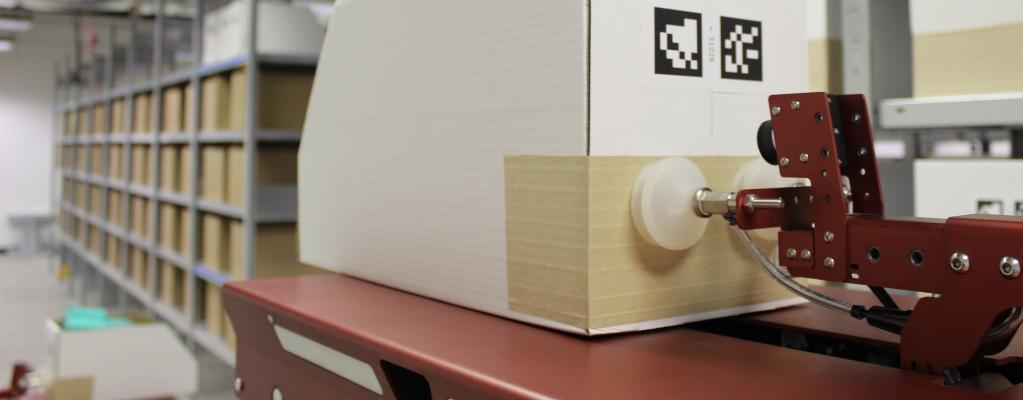

With RaaS, AMRs are deployed within the existing infrastructure of a company’s warehouse and sync with current warehouse management systems (WMS). inVia’s robots map the most efficient routes and can even shift workflows in real time. This allows a company to accommodate changing needs, routes and product placement based on current demand, popular inventory, busy seasons and other factors. Companies can start with 10 robots in the warehouse and add as needed without disrupting current warehouse processes.

inVia’s RaaS model operates based on a goods-to-person (GTP) workflow. A major benefit gained through GTP is a significant increase in efficiency and productivity (up to 500% compared to traditional, non-automated warehouses). It eliminates nearly all walking for picking operations in the aisles as items are delivered via robots directly to workers at optimized pick stations. The employee no longer spends time traversing across the entire warehouse to complete the order fulfillment process. Team members have more time to inspect the items being picked and focus on other high-level tasks – like increasing accuracy, managing automated operations, customizing consumer packaging and more.

The GTP workflow also addresses the inefficiency of workers walking the aisles to complete costly operations related to replenishment, putaway, and even cycle counting. Lastly, with the drastic reduction of labor in the aisles and improvements in accuracy, companies utilizing GTP solutions see decreased costs in overall inventory shrinkage and even customer returns.

Preparedness of your team

Consider your current team on the warehouse floor and how to ensure they experience a seamless transition as you incorporate automation. The solution will ideally make their jobs easier and safer, supporting them in their role. Is your team overwhelmed at the thought of working alongside (or assisting with the operational needs of) robots? Do you have the right technical resources to manage a fleet of robots? The simplicity of the platform can alleviate these potential pain points. While many automation solutions require robotics experts and advanced technical skills to operate, utilizing RaaS with an advanced robot fleet management system, operating and working with the robots is simple.

The team at inVia handles the introduction of robots into your warehouse from start to finish, from discovery to design to simulation—even the actual deployment of the robots. The entire process is coordinated in advance of the arrival of robots, so the actual rollout only takes days, not months or even years compared to traditional GTP solutions. Customers don’t have to hire a robotics team or army of engineers to automate their warehouse.

How the robots will be managed

In terms of day-to-day management, the customer utilizes the intuitive inVia Robot Management System to monitor their meet and ongoing performance and fulfillment metrics. This means the customer is in control of the process, improving productivity and lowering the total cost of moving goods through their warehouse.

As innovation in artificial intelligence and robotics continues to evolve at a rapid pace, organizations are under an increasing amount of pressure to predict costs and achieve a speedy return on investments. Technology that is quite cutting edge today may not be relevant in a few years time. With RaaS, inVia owns and maintains the robot fleet throughout the life of the contract (which includes all parts and service). The hardware and software components are updated for optimized performance and at the robot’s end of life, it’s replaced with a new model at no additional cost.

Given its low-risk nature, predictable costs, ease of use, and flexible, scalable features, RaaS is becoming an increasingly popular choice for e-commerce companies. Learn more about the subscription-based model here.