Online shoppers have certain expectations that online retailers need to meet if they want to generate customer loyalty. Topping that list is speed and accuracy.

Long gone are the days of mail-order, when customers flipped through thick catalogs of merchandise from Sears or L.L. Bean and mailed in paper order forms, hoping that the quantity, size, and color of the items they’d ordered will be in stock.

Modern e-commerce websites process orders 24/7, letting customers know if their items are available and when they’ll arrive. Orchestrating this (hopefully) seamless shopping experience are various software systems that take the input from a shopper’s computer or phone and translate that information into all the steps necessary to get the order to the customer in 1-2 days.

Understanding these systems and their functions can require wading through an alphabet soup of acronyms, but we’re here to help. Some of these software systems complement other systems, while others provide features that overlap. Let’s dive into the basics.

Order Management System (OMS)

At the fundamental level, an order management system is software used for order entry and processing. In broader terms, an OMS tracks orders, sales, inventory, and fulfillment operations—every process needed to get products to the customers that bought them.

Enterprise Resource Planning (ERP)

The term enterprise resource planning typically refers to a suite of integrated software applications that companies use to manage day-to-day business processes, such as accounting, HR, project management and supply chain operations. ERP systems help all the different departments in a company communicate more effectively and share information. The most well-known names in ERP are Microsoft, Oracle, and SAP.

Labor Management System (LMS)

A labor management system is software that monitors employee activity and reports productivity levels. It helps warehouse managers track workers’ performance and allocate resources accordingly. An LMS can also provide incentive-based tracking and analytics to award performance-based bonuses.

Warehouse Control System (WCS)

Warehouse control system software directs the activity inside a warehouse or distribution center in real-time, managing the movement of pallets, cases, cartons or totes on conveyors and large automated storage and retrieval or sortation systems.

Warehouse Execution System (WES)

Warehouse Execution System software organizes, sequences and synchronizes the resources necessary to complete the shipment of products. A WES is a hybrid system that combines specific warehouse management system functionality with warehouse control system functionality to track and control processes in real-time.

Warehouse Management System (WMS)

A warehouse management system is software that’s designed to manage the day-to-day operations of a warehouse or distribution center, including receiving inventory, storage, picking, packing, shipping, and replenishment. Such systems help warehouse managers in their daily planning, organizing, staffing, and utilization of resources. The big names in WMS are HighJump, Manhattan Associates, and JDA.

Adding Robotics and Automation to your Warehouse

If you are running an e-commerce business, chances are you’ve already invested in a WMS and any number of other software applications. But if you’re looking to take your operations to the next level, it’s time to consider adding robotics and automation. And that’s where we come in.

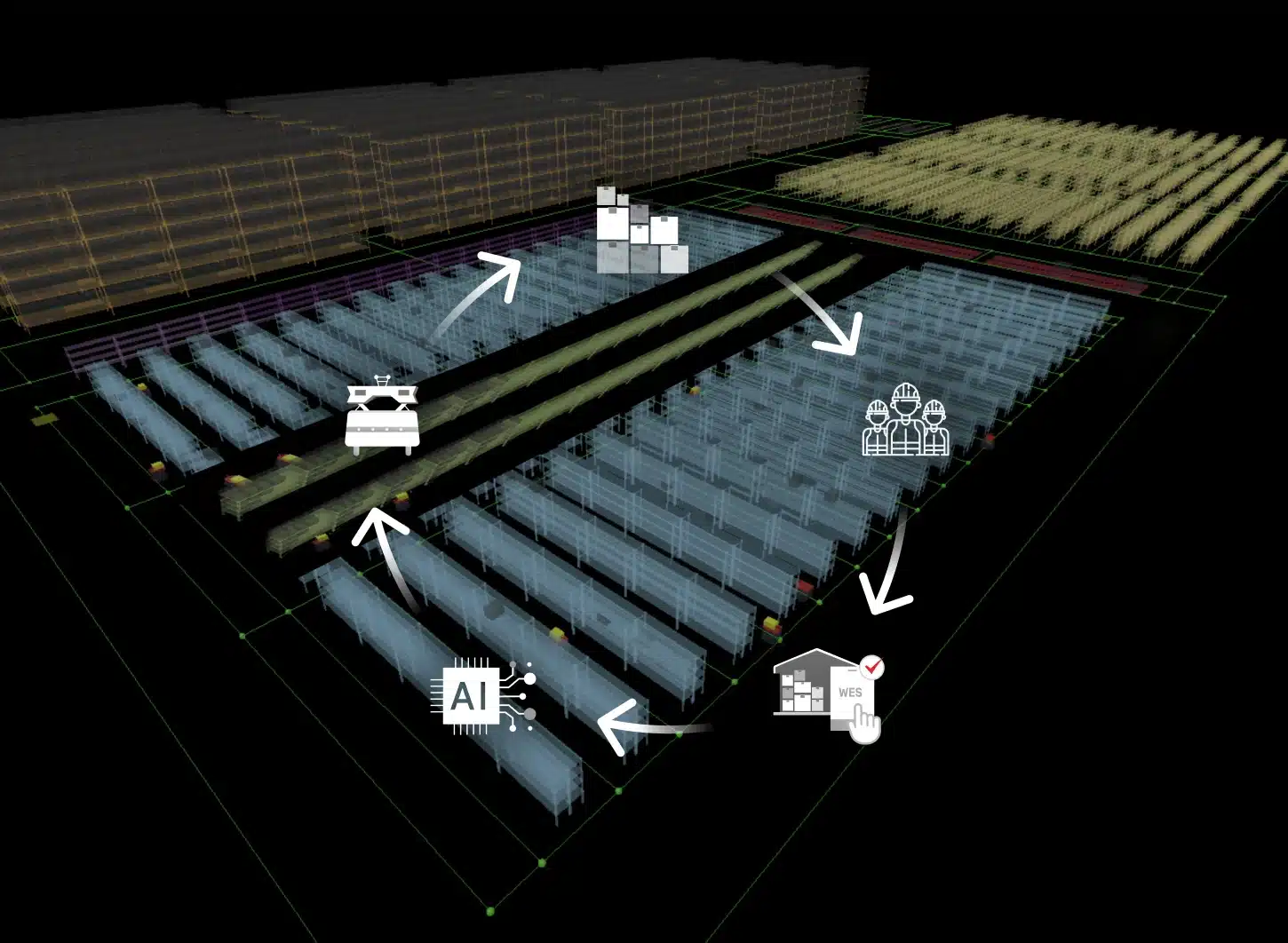

A crucial component of inVia Robotics’ fully autonomous robotic picking system is our WES software, which complements any WMS and solves one of the biggest challenges in traditional systems integration. It includes inVia Connect, a communications and translation tool that enables the quick and easy exchange of data between inVia’s system and any WMS.

Our portal and dashboards let you see the location of robots and inventory, as well as productivity levels, from almost any smart device. You can monitor your operations and make informed, real-time decisions wherever you are.

Our system is cloud-based and gives you the ability to input, manage and leverage unlimited points of data to make your warehouse smarter. We also continually update the system through AI and machine learning. Updates are included with your system, so you are always ahead of the technology curve.

Best of all, when you deploy our system, you can jettison many of the redundant applications that are clogging up your servers. We handle picking, inventory, replenishment, cycle counting, sortation and returns with ease.

Interested in putting the power of mobile robotics to work in your warehouse? Request a Demo.