For order fulfillment businesses, idle time is a formidable adversary. It can sneak up due to many different reasons – a bottleneck in your workflow or inefficient planning that leaves your team waiting for instructions. The impact? Slower order fulfillment, higher costs, and, let’s not forget, a bit of frustration all around.

Understanding Idle Time in Warehouses

Idle time in warehouses refers to a period of time when resources (people or equipment) aren’t actively engaged in productive tasks. These pauses in operations, often overlooked in the daily whirlwind of tasks, are where businesses can find potential efficiency gains.

For example, imagine a warehouse where a worker repeatedly waits for instructions from a warehouse manager who is busy with another task or faced with unexpected equipment breakdowns. Or, an instance where a worker spends a significant amount of time walking back and forth between the reserve and picking area because items are not organized efficiently. Waiting for instructions or equipment and inefficient walking time, during which the worker is not actively picking, packing, or processing goods, are typical examples of idle time.

Traditionally, warehouse managers tackle idle time through manual planning and scheduling, as well as preventative maintenance to minimize equipment downtime. Cross-training warehouse team to handle multiple tasks is another method to optimize actual production time. However, this method has limitations, as it is unable to adapt in real time to unexpected changes or issues. As a result, it leads to inefficiencies, with idle time negatively impacting overall productivity.

How inVia’s Intelligent Automation Tackles Idle Time

In the quest to turn idle time into productive hours, artificial intelligence (AI) is a revolutionary ally. It can sift through vast amounts of data, identify idle time patterns, and focus on continuous improvement with a speed and accuracy that far exceeds human capability.

Below, we delve into the core strategies inVia’s technology employs to transform idle time into productive, efficient operations.

1. The Big Picture – AI-driven workflow optimization

Cutting down idle time in warehouses is all about looking at the big picture. You can’t just optimize one area, such as picking, to eliminate bottlenecks because all tasks in the warehouse are interconnected. A delay in one workflow can cascade through the system, escalating idle time.

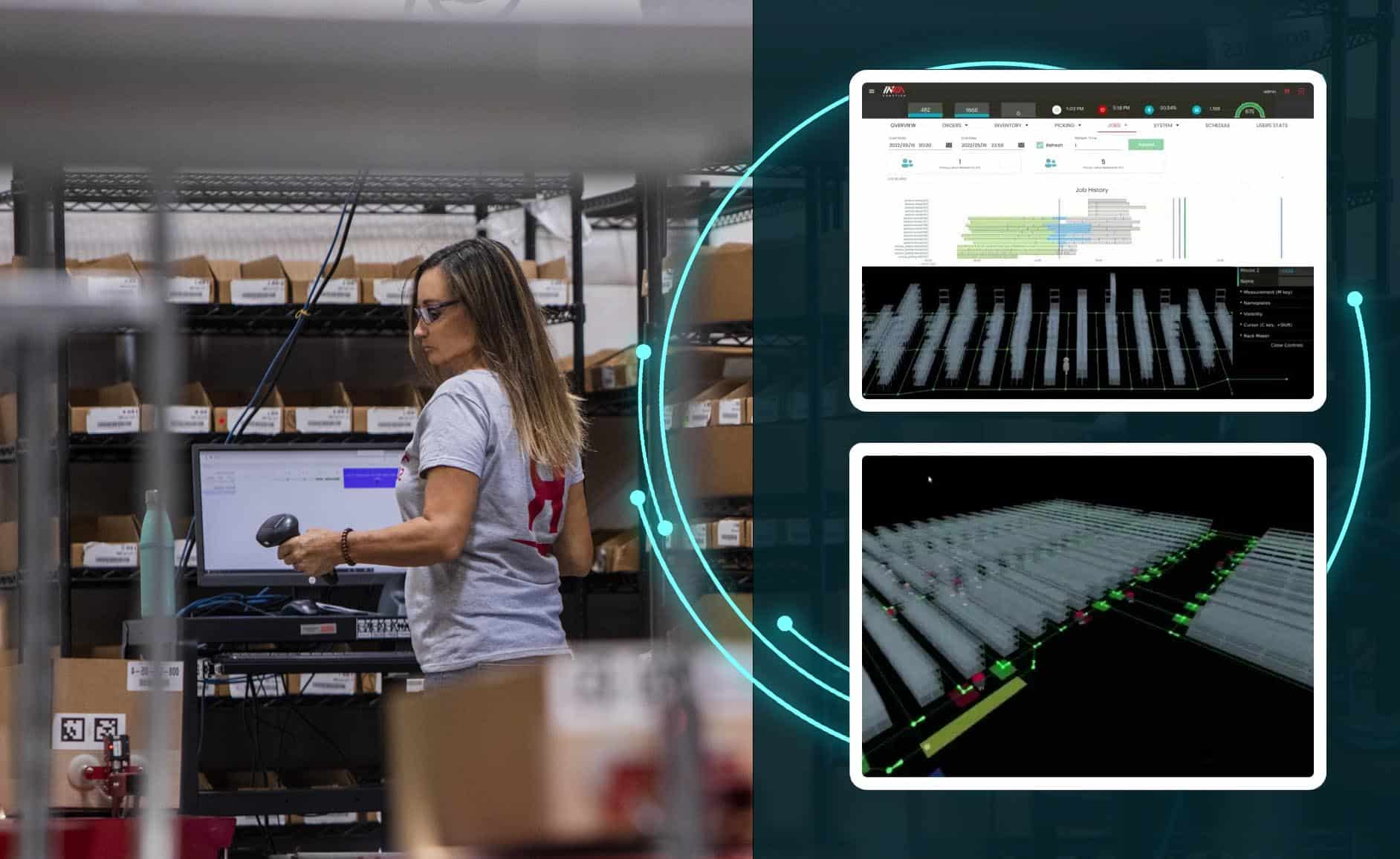

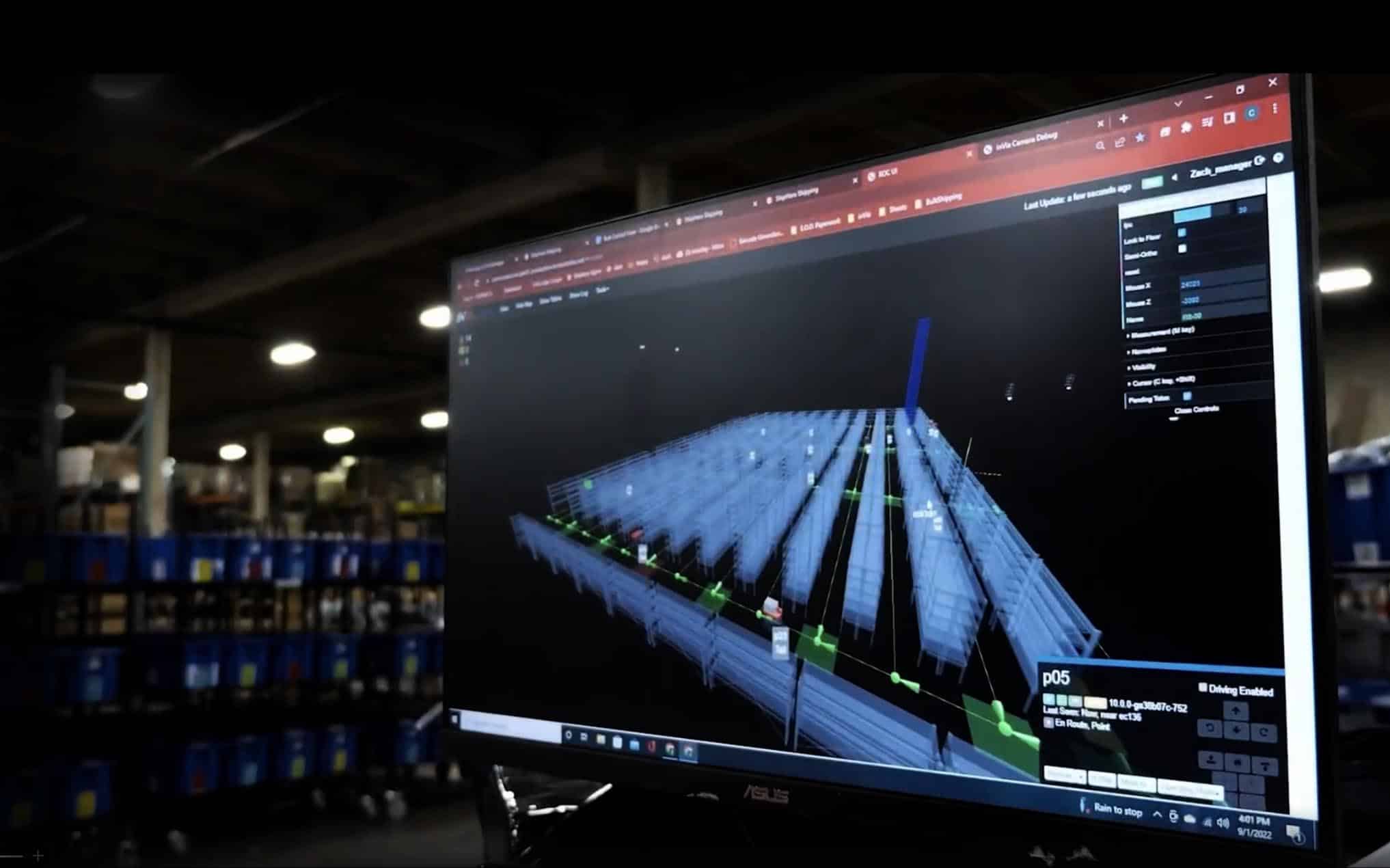

inVia’s advanced AI untangles those dependencies. It balances every fulfillment task to ensure you get the highest throughput while still achieving SLAs. It makes more than 1 million decisions per day to streamline operations. Synchronizing all fulfillment tasks and eliminating bottlenecks ensures that every component of the warehouse operates in harmony. This synchronization is key to eliminating idle time.

inVia Logic Warehouse Execution System (WES) software

2. Smart Task Assignment

Warehouse conditions are anything but static; they change from minute to minute. Whether it’s an unanticipated delay, equipment failure, or a sudden change in order priorities, these hiccups can quickly lead to idle time if not managed promptly. That’s why inVia’s system constantly recomputes this plan, reallocating labor as needed to keep orders moving without delays.

3. Clear Instructions for Effortless Execution

Knowing what to do is one thing, but knowing how to do it quickly and efficiently is another. With AI-driven planning and dynamic task assignments in place, effective employee guidance is the next priority.

The inVia PickMate productivity tool equips workers with detailed, color-coded instructions for each task. Employees receive GPS-like directions within a warehouse’s complex layout. With the help of the Pick-to-Color technology, workers know exactly where to go and what to pick/place/move at all times. This streamlines the workflow and significantly reduces the time spent on each order.

inVia PickMate – Pick-to-Color technology

4. Eliminating Unnecessary Walking

5. Goods-to-Person Automation: Taking efficiency to a whole new level

The final piece of inVia’s strategy to eliminate idle time is our innovative inVia PickerWall, a cutting-edge Goods-to-Person (GTP) automation solution. Imagine a wall that dynamically adjusts to what needs to be picked, brought directly to workers by mobile robots (AMRs). This isn’t about avoiding the walk; it’s about eliminating it altogether. Workers stay behind the inVia PickerWall, and the goods come to them, tailored specifically to the orders they are assembling.

inVia PickerWall Goods-to-Person (GTP) robotic automation

Tackling idle time in warehouses is a multifaceted challenge that inVia Robotics addresses through a combination of AI-driven planning, dynamic task allocation, clear instructional guidance, and innovative goods-to-person automation. This comprehensive strategy underscores the potential of intelligent automation to revolutionize warehouse operations, making them more efficient, adaptable, and capable of meeting the demands of today’s fast-paced market.