CASE STUDY

Gnarlywood reduces labor cost and boosts productivity

At a Glance

- Unprecedented growth requires immediate productivity gains

- Improve the efficiency of current employees

- Reduce the need to hire temp workers

Solution:

inVia’s phased approach to automation adoption: We first deployed inVia Logic, AI-powered warehouse execution system (WES), to optimize and deliver value across every workflow, then deployed inVia PickerWall robotic solution to automate the fulfillment operations.

Result:

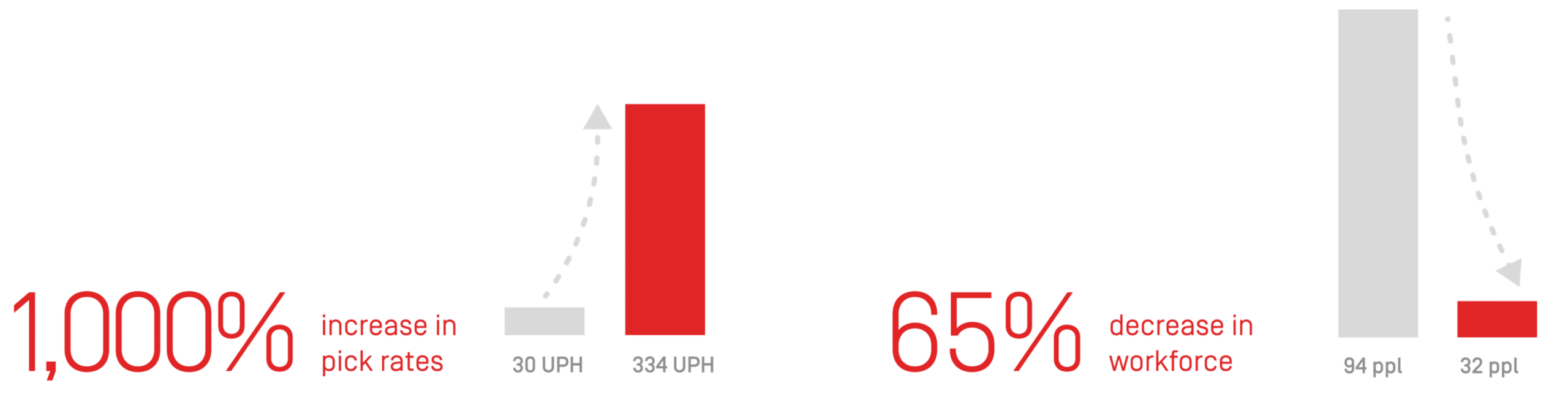

Gnarlywood increased pick rates by 1,000% and decreased labor cost by 65%.

______________

Founded in 2012, Gnarlywood Group manages e-commerce fulfillment for some of the world’s biggest entertainment brands. They manage storage, fulfillment, and shipping for a variety of products.

Gnarlywood faced a significant surge in demand for its services. To keep up with this growth, the company had to find ways to improve productivity. Due to the labor shortage, Gnarlywood wanted to avoid the need to hire more staff and make the most of their existing workforce while keeping costs under control.

“We wouldn’t have made it through this year without inVia. They completely changed the way we do business. We now meet same-day shipping SLAs. We increased pick rates and reduced new-hire training from days to ~30 minutes. We’ve been able to retain quality labor and hand out the highest pay raises in company history”.

Dayton Hicks, Gnarlywood Founder and CEO

______________

The Solution

inVia’s Software Automation immediately increased productivity 2-3x.

inVia Robotics first deployed its warehouse automation software. Using Artificial Intelligence, the system analyzed SLA requirements and built an optimization plan to deliver value across all fulfillment points in the warehouse. The deployment of inVia’s software-only solution helped Gnarlywood better position inventory, direct pickers to take the most efficient path, and coordinate the tasks and movements of warehouse staff and equipment.

inVia deployed inVia PickerWall robotic solution to maximize efficiency.

inVia’s Robotics-as-a-Service (RaaS) subscription allowed Gnarlywood to easily upgrade from software-only to inVia PickerWall robotic automation to automate order picking, replenishment and putaway. inVia Picker robots work autonomously to deliver inventory to a dynamic hyper-dense pick/put wall. Employees work on the other side, pulling products and sorting into order bins. inVia PickerWall robotic automation further boosted productivity reaching 10x increase over traditional picking.

inVia’s comprehensive fulfillment system allowed for reduction in labor cost.

As a result of implementing inVia Logic WES software and inVia PickerWall robotic automation, Gnarlywood lowered labor cost by 65%.

The company avoided the need to hire temps during peak season and increased accuracy to 99.9%.

______________

The Result

Gnarlywood increased pick rates by 1,000% and decreased labor cost by 65%.

“inVia provides a unique solution that includes the most advanced warehouse technology and the ability for us to integrate it over time with maximum benefit and minimal disruption.

We needed a technology partner that could deliver immediate productivity gains, as well as a path to full warehouse automation in parallel with our plans for business growth.”

Dayton Hicks, Founder and CEO at Gnarlywood

Request a Demo

Did you know that you can boost your productivity 2-3x with inVia Logic's AI automation solution and 5x when you add inVia Picker autonomous mobile robots?

Complete the form and a member of our team will contact you to conduct a demo that explains how you can increase your productivity with the inVia system.